Structural Health Monitoring

Simulation based digital twins and predictive maintenance of infrastructure

WeStatiX SHM combines true simulation-based Digital Twins with Artificial Intelligence into a revolutionary platform for infrastructure monitoring. It can be applied to any kind of structure, from bridges to tunnels, and even to slopes and rock walls, to provide accurate insight into the current and future behavior of the monitored object. WeStatiX SHM can be used to improve structure safety, optimize monitoring costs, and reduce the environmental impact of the build world. All in your favorite browser.

What it is and what it is for

What is structural monitoring and what is it for

Structural monitoring refers to the process of continuously or periodically assessing the condition and behavior of physical structures, such as buildings, bridges, dams, pipelines, and other infrastructure. The primary purpose of structural monitoring is to ensure the safety, reliability, and performance of these structures over time. By collecting real-time data and analyzing it, engineers and maintenance personnel can identify potential issues, assess structural health, and make informed decisions about maintenance, repairs, or necessary interventions.

Strain And Stress

Monitoring the structural response to applied loads and environmental conditions helps identify if the structure is experiencing excessive strain or stress that could lead to failure.

Displacement And Deflection

Tracking the movement and deflection of structural elements can provide valuable insights into any excessive or abnormal behavior.

Vibration

Monitoring vibrations can detect anomalies, such as resonance or unusual dynamic behavior, which may indicate structural weaknesses.

Temperature and Humidity

Changes in temperature and humidity can affect the integrity of certain materials, and monitoring these factors can help identify potential issues.

Load Distribution

Understanding how loads are distributed across a structure can help engineers ensure that it is operating within safe limits.

Cracks and Damage

Continuous monitoring can detect the development of cracks or damage to the structure, allowing for timely repairs.

Why structural monitoring is important

Structural monitoring is crucial for ensuring the safety, reliability, and performance of infrastructure. By proactively identifying potential issues and responding to them promptly, it helps prevent accidents, extends the lifespan of structures, and minimizes the overall life-cycle costs of maintaining and operating critical assets.

Cost Savings

Timely detection of structural issues and effective maintenance strategies can lead to substantial cost savings in the long run. Preventive measures are often less expensive than reactive repairs after significant damage has occurred.

Regulatory Compliance

Many industries and regions have specific regulations and codes that require structural monitoring for certain types of infrastructure. Complying with these regulations is essential to avoid legal and financial consequences.

Real-Time Data

Continuous monitoring provides real-time data about the structural behavior, allowing for immediate responses to any anomalies or critical events.

Risk Assessment

Regular monitoring allows engineers to assess the structural health and potential risks associated with a specific structure. This information is crucial for decision-making regarding the safe use of the structure or for determining the need for structural upgrades.

Validation of Design Assumptions

Monitoring real-world performance helps validate the assumptions made during the design phase. It provides essential feedback to engineers, enabling them to refine future designs and ensure they meet safety and performance standards.

Environmental Impact

Efficient monitoring reduces unnecessary maintenance and repair activities, leading to lower resource consumption and waste generation. This benefits the environment by reducing the ecological footprint associated with infrastructure maintenance.

Safety

The safety of people and the surrounding environment is the most crucial aspect. Structural failures can lead to catastrophic consequences, resulting in injuries, loss of life, and significant damage to property. By continuously monitoring structures, potential issues can be detected early, allowing for timely interventions and preventing disasters.

Preventive Maintenance

Structural monitoring enables the identification of deterioration or damage in its early stages, which allows for targeted and cost-effective preventive maintenance. Addressing problems before they escalate can extend the lifespan of structures and reduce the need for extensive repairs or replacements.

Performance Optimization

Monitoring data provides valuable insights into how structures respond to different loads, environmental conditions, and other factors. By understanding their behavior, engineers can optimize the design and operational efficiency of structures.

Our revolutionary approach

A unique cloud-based platform that is able to interpret the physical behaviour of a structure based on data provided by installed sensors, and predict its future behaviour through the use of artificial intelligence.

Real-time monitoring

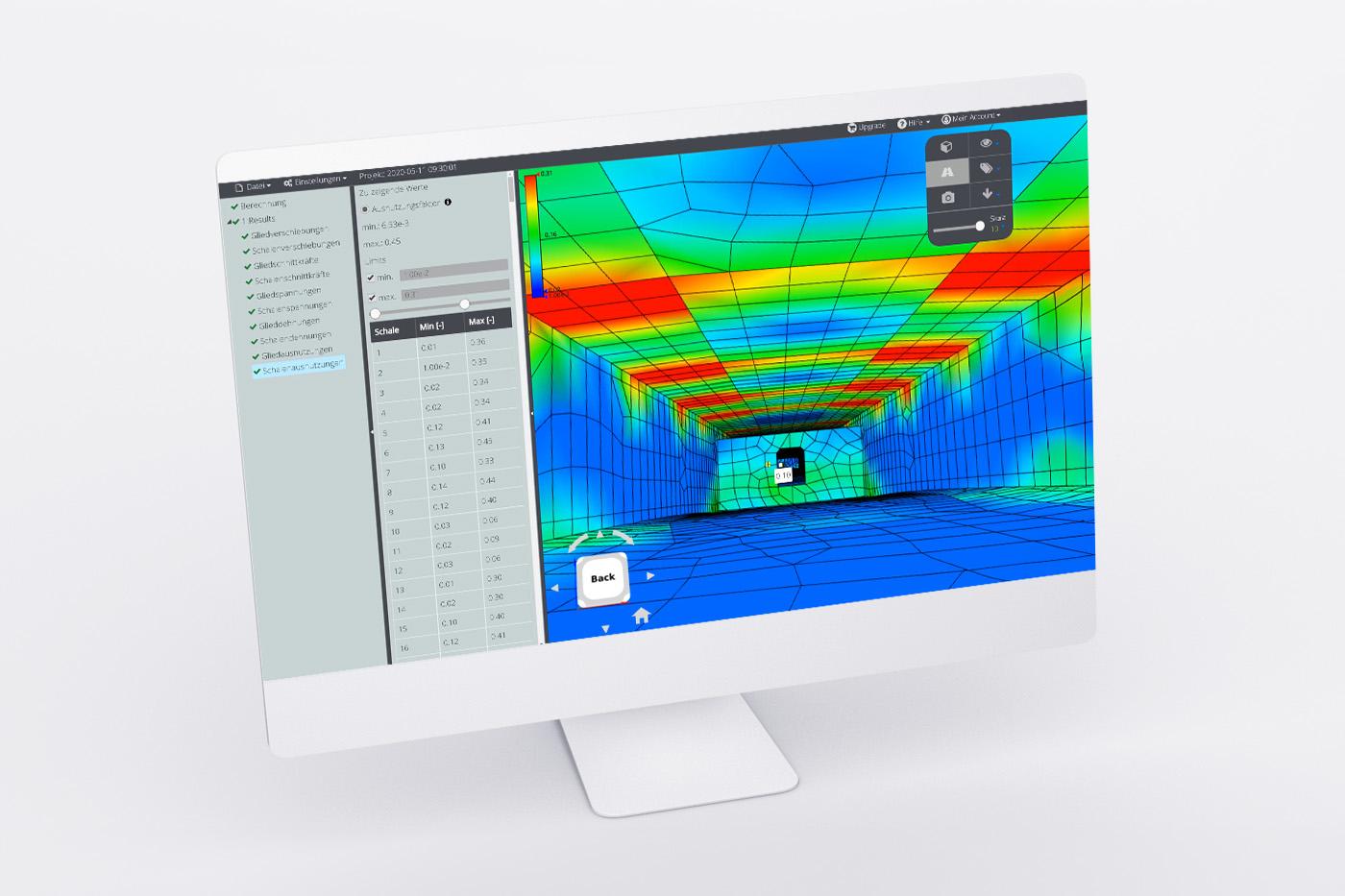

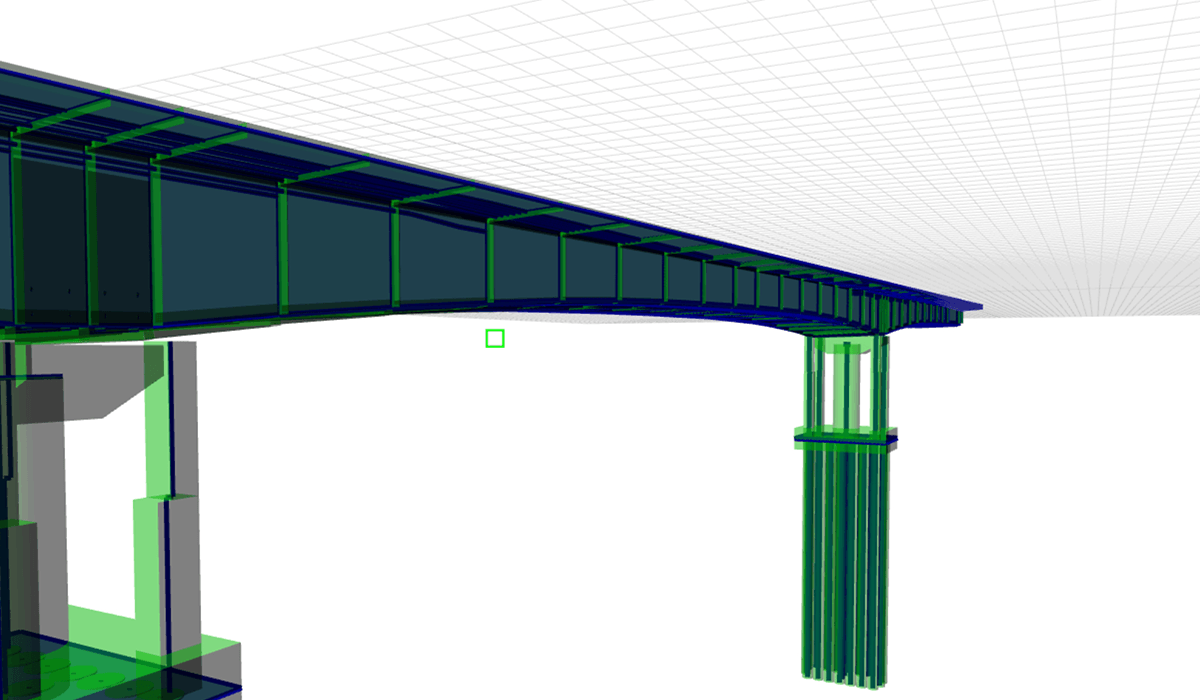

Structural health monitoring via digital twins

With WeStatiX SHM, you can create custom digital twins for real-time monitoring of existing structures in the cloud. This is possible for many kinds of infrastructure, such as bridges, rock walls, slopes, dams, buildings, and much more! The system is based on the combination of several innovative digital technologies, and thanks to artificial intelligence algorithms it is a powerful tool for the inspection and maintenance of any monitored object.

Learn moreCloud computing technologies

Cloud based structural monitoring

This approach offers several advantages over traditional on-premises systems, including scalability, accessibility, and the ability to leverage advanced analytics and machine learning. Here's an overview of how WeStatiX SHM works:

- Sensor Deployment

- Data Acquisition

- Data Transmission to the Cloud

- Cloud Computing

- Data Analysis and Visualization

- Machine Learning and Predictive Analytics

- Alerts and Notifications

- Accessibility

- Scalability

Why it works

Our digital twins perform the continuous evaluation of the structural health on the basis of IoT sensors data, numerical simulation, and artificial intelligence. The digital twin model is not only a 3D model, but is the continuously updated counterpart of the physical structure.

Look at the meaning of data

The simulations on the digital twin are able to evaluate globally the state and the risk of the structure, based on local measurement of the installed sensors.

Measurement-based simulations

The FE-simulations are continuously performed on the basis of measured or identified actions, such as loads, aging, temperature, and more, allowing for a much higher level of fidelity compared to the assumptions made during design.

Look into the structure

The visual observation (even if automatic) is only able to evaluate damage that already took place. The structural collapse can very often only be predicted by evaluating the stress state of the structure through numerical simulation.

Look into the future

By using artificial intelligence the historic data about the monitored structures are used to build an extensible self-learning system, that becomes better over time.

How it works

The system is based on the combination of several innovative digital technologies

- Development of a reliable 3D digital twin of the object

- Cloud-based visualization that enables virtual inspections

- Automatic execution of numerical FE simulations

- Continuous model calibration using inverse analysis

- Predictive analysis through Artificial Intelligence

- BIM (Building Information Modelling)